Introduction of parts logistics business

Transfer Logistics:

It is also called milk run, which is different from the traditional delivery system. Its main feature is the change of logistics service subject. The main engine factory informs the supplier to prepare the goods in the form of order, and entrusts the third party logistics company to pick up the goods on site. The third party logistics company will deliver the supplier's goods to the host plant according to the quality and time requirements of the host plant.

Factory logistics:

Fengshen logistics carries out production logistics auxiliary management through advanced production management system, and monitors all indicators of Q, C, D, s and m in the whole process. With professional, efficient and high-quality on-site management, we can provide all-round production logistics services for the production processes of automobile manufacturers, such as stamping, welding, coating, resin and general assembly. Business covers: domestic and foreign products, internal stamping parts, imported (KD) parts arrival acceptance, transfer and warehousing, in warehouse management, sorting, centralized distribution / sequencing operation, in plant transfer, distribution online, line side management, container recycling, folding and packing, container return, etc.

Engine Logistics:

Fengshen logistics undertakes the production logistics business of engine and gearbox in the main engine factory, including casting, processing, assembly and other links. The storage area is 33000 m2, and the logistics service covers the acceptance and warehousing, in warehouse management, centralized distribution, supply and container recycling of more than 900 engines and transmission parts, until the final finished products are put into storage, delivery supply and unqualified product management.

VMI(Vendor managed inventory):

VMI is a cooperative strategy which aims to get the lowest cost for both users and suppliers. Under a common agreement, the supplier manages the inventory, and constantly supervises the implementation of the agreement and revises the content of the agreement, so that the inventory management can be continuously improved. Fengshen logistics provides logistics services for suppliers, such as centralized storage and distribution of parts, transfer packaging, sub packaging of parts, online distribution and delivery agent.

Tire press fit:

Fengshen logistics introduces an efficient, economic and reliable tire pressing line, with more than 30 sets of imported production equipment of various types, and the press fitting line capacity reaches 4.5 million pieces / year. It mainly provides logistics services for vehicle assembly plants such as tire sub loading and synchronous distribution online.

Logistics equipment:

Fengshen logistics has professional logistics equipment development, design, manufacturing capabilities, integration of lean production concept, design and manufacturing to "safe and reliable loading, convenient and flexible operation" as the principle, to minimize the storage and transportation costs and labor intensity of workers as the goal, combined with the actual needs of different customers, to provide customers with efficient, practical, beautiful, economic and durable logistics equipment With products.

Export packaging:

Fengshen logistics has accumulated rich packaging design and manufacturing experience, covering more than 6000 kinds of products in various fields, such as spare parts packaging (domestic and export sales), automobile KD packaging, etc.

物流技术

基于与汽车制造企业紧密联动而实施的前瞻性的物流设计,使产品和服务能更加便捷的深入到制造业第一线,甚至于从汽车制造企业建设规划的初期,东风物流就开始介入同步进行相应的物流设计、布局规划、生产导入准备以及试运行,实现与汽车主机厂的设计、规划与试生产同步,贴身打造汽车供应链的各种服务管理方案,为客户效能提升创造了价值。

公司长期致力于汽车物流专业技术领域的创新研究与实践应用,通过现代物流技术提高物流运作效率、实现物流过程可视化,以及科学规划物流网络布局。公司下设物流技术中心,主要在物流规划咨询、IT信息系统和装备自动化等领域展开研究与应用。

Logistics technology

The forward-looking logistics design based on the close linkage with the automobile manufacturing enterprises makes the products and services more convenient to penetrate into the first line of the manufacturing industry. Even from the early stage of the construction planning of the automobile manufacturing enterprises, Fengshen logistics began to intervene in the corresponding logistics design, layout planning, production import preparation and trial operation, so as to realize the design, layout planning, production import preparation and trial operation of the automobile manufacturers Planning and trial production are synchronized to create various service management solutions of automobile supply chain, which creates value for the improvement of customer efficiency.

The company has long been committed to innovative research and practical application in the field of automobile logistics technology, improving the efficiency of logistics operation through modern logistics technology, realizing the visualization of logistics process, and scientifically planning the logistics network layout. The company has a logistics technology center, mainly in logistics planning consulting, it information system and equipment automation and other fields to carry out research and application.

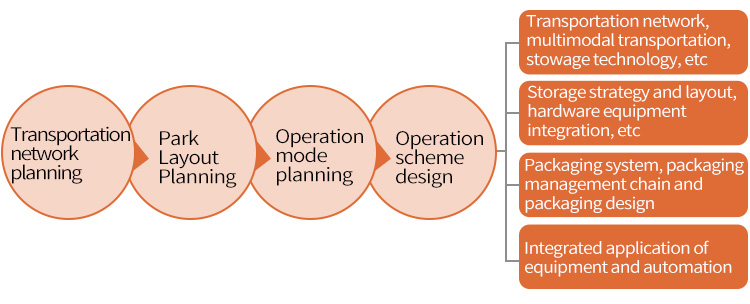

Logistics planning consultation:

Fengshen logistics provides the overall planning consultation of automobile logistics supply chain, including plot function planning, park layout planning, operation mode planning and operation scheme planning, etc. The operation mode and scheme planning includes the planning of storage, transportation, packaging, equipment and automation. Planning consulting services can provide technical solutions covering the whole supply chain of procurement logistics, sales logistics, production logistics and recycling logistics.

Logistics information system:

Fengshen logistics has independently developed it information system serving automobile logistics supply chain, including WMS warehouse management system, TMS transportation management system, SCV supply chain visualization system, Les logistics execution system, CIP customer interaction platform, etc. through it network technology, it optimizes the supply chain resource configuration, realizes the information transparency in the whole process of automobile logistics, and provides customers with more efficient and convenient Logistics service of jiejie.

Logistics equipment and automation:

Fengshen logistics has equipment and automation research room, which is mainly responsible for the standardization, technology improvement and key application in the field of equipment and automation, and integrates the concept of lean production to minimize the storage and transportation costs and labor intensity of workers as the goal, combined with the actual needs of different customers, to provide efficient and practical technical improvement solutions for customers.